Scientists Develop Skin That Heals, Feels, and Looks Human – World Pakistan

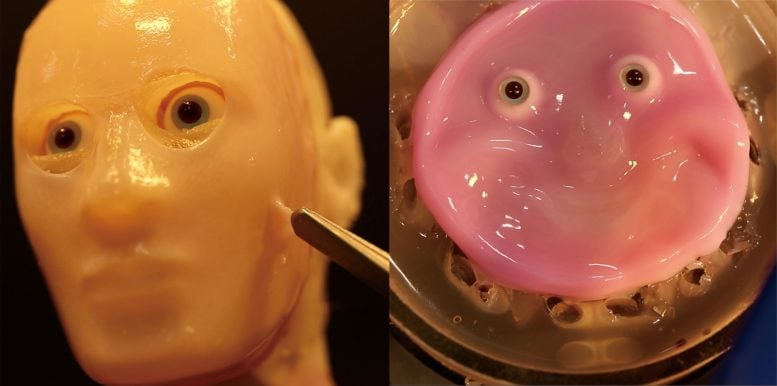

A new technique developed by Professor Shoji Takeuchi’s team allows for the effective binding of engineered skin to humanoid robots, improving their appearance and functionality. This could revolutionize fields like medical research and cosmetic testing. Credit: ©2024 Takeuchi et al. CC-BY-ND

Scientists have developed a method for attaching engineered skin to robots, improving their functionality and appearance.

Japanese researchers have developed a method to bind engineered skin tissue to humanoid robots, enhancing their mobility, self-healing abilities, and sensory capabilities. This technique involves special perforations that allow the skin to adhere better and move with the robot’s mechanical parts. The advancements could significantly impact medical research, cosmetic testing, and the development of more lifelike robots.

Advancements in Biohybrid Systems

The research was led by Professor Shoji Takeuchi of the University of Tokyo, a pioneer in the field of biohybrid robotics. His lab, the Biohybrid Systems Laboratory, has created mini robots that walk using biological muscle tissue, 3D-printed lab-grown meat, engineered skin that can heal, and more. It was during research on the last of these items that Takeuchi felt the need to take the idea of robotic skin further to improve its properties and capabilities.

“During previous research on a finger-shaped robot covered in engineered skin tissue we grew in our lab, I felt the need for better adhesion between the robotic features and the subcutaneous structure of the skin,” said Takeuchi. “By mimicking human skin-ligament structures and by using specially made V-shaped perforations in solid materials, we found a way to bind skin to complex structures. The natural flexibility of the skin and the strong method of adhesion mean the skin can move with the mechanical components of the robot without tearing or peeling away.”

The engineered skin tissue and the way it adheres to the underlying complex structure of the robot’s features were inspired by skin ligaments in human tissues. Credit: ©2024 Takeuchi et al. CC-BY-ND

Innovative Skin Attachment Techniques

Previous methods to attach skin tissue to solid surfaces involved things like mini anchors or hooks, but these limited the kinds of surfaces that could receive skin coatings and could cause damage during motion. By carefully engineering small perforations instead, essentially any shape of surface can have skin applied to it. The trick the team employed was to use a special collagen gel for adhesion, which is naturally viscous so difficult to feed into the minuscule perforations. But using a common technique for plastic adhesion called plasma treatment, they managed to coax the collagen into the fine structures of the perforations while also holding the skin close to the surface in question.

The new anchoring method allows flexible skin tissue to conform to any shape it’s attached to. In this case, a relatively flat robotic face is made to smile and the skin deforms without constraining the robot, returning to its original shape afterwards. Credit: ©2024 Takeuchi et al. CC-BY-ND

“Manipulating soft, wet biological tissues during the development process is much harder than people outside the field might think. For instance, if sterility is not maintained, bacteria can enter and the tissue will die,” said Takeuchi. “However, now that we can do this, living skin can bring a range of new abilities to robots. Self-healing is a big deal — some chemical-based materials can be made to heal themselves, but they require triggers such as heat, pressure, or other signals, and they also do not proliferate like cells. Biological skin repairs minor lacerations as ours does, and nerves and other skin organs can be added for use in sensing and so on.”

Other methods to bind skin tissue to solid structures come with limitations. This new method can work on complex, curved, and even moving surfaces. Credit: ©2024 Takeuchi et al. CC-BY-ND

Future Implications and Enhancements

This research was not just made to prove a point, though. Takeuchi and his lab have a goal in mind for this application that could help in several areas of medical research. The idea of an organ-on-a-chip is not especially new and finds use in things like drug development, but something like a face-on-a-chip could be useful in research into skin aging, cosmetics, surgical procedures, plastic surgery and more. Also, if sensors can be embedded, robots may be endowed with better environmental awareness and improved interactive capabilities.

“In this study, we managed to replicate human appearance to some extent by creating a face with the same surface material and structure as humans,” said Takeuchi. “Additionally, through this research, we identified new challenges, such as the necessity for surface wrinkles and a thicker epidermis to achieve a more humanlike appearance. We believe that creating a thicker and more realistic skin can be achieved by incorporating sweat glands, sebaceous glands, pores, blood vessels, fat and nerves. Of course, movement is also a crucial factor, not just the material, so another important challenge is creating humanlike expressions by integrating sophisticated actuators, or muscles, inside the robot. Creating robots that can heal themselves, sense their environment more accurately and perform tasks with humanlike dexterity is incredibly motivating.”

Reference: “Perforation-type anchors inspired by skin ligament for robotic face covered with living skin” by Michio Kawai, Minghao Nie, Haruka Oda and Shoji Takeuchi, 25 June 2024, Cell Reports Physical Science.

DOI: 10.1016/j.xcrp.2024.102066

Funding: This work was supported by JSPS Grants-in-Aid for Scientific (KAKENHI), Grant Number 21H05013 and 24K21079.