Revolutionary Catalyst Coating Technology Skyrockets Fuel Cell Performance in Just 4 Minutes

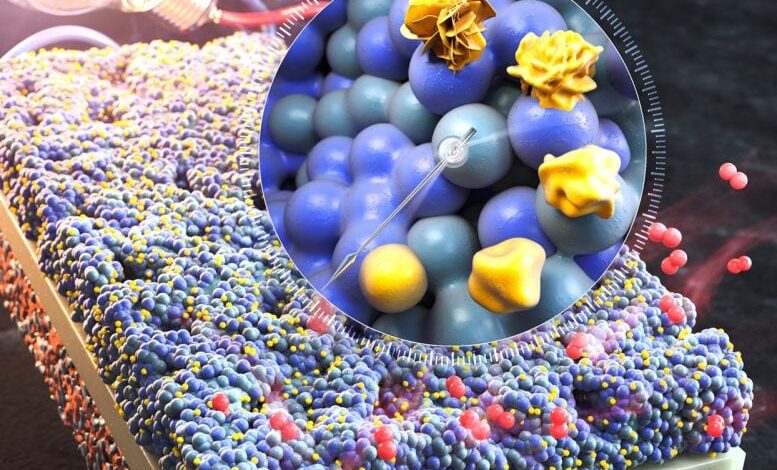

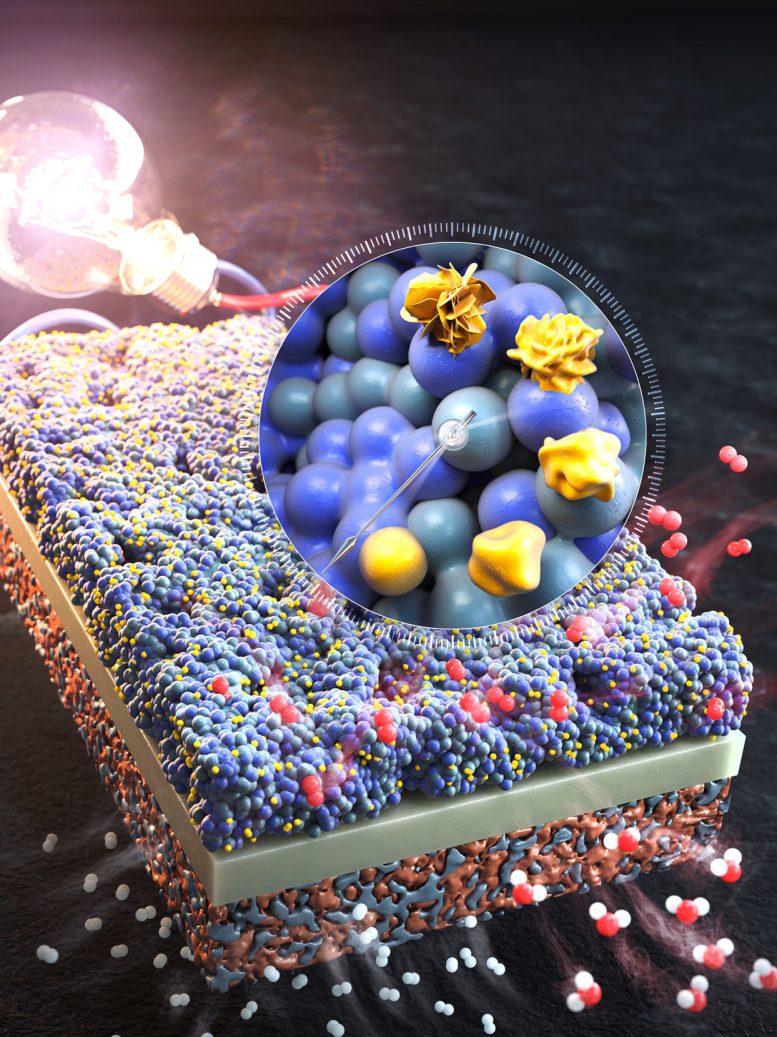

A collaborative research team has developed a new catalyst coating technology that enhances solid oxide fuel cell performance threefold in just four minutes, offering potential advancements in energy conversion technology. Credit: Korea Institute of Energy Research (KIER)

A new oxide catalyst coating technique significantly enhances the performance of solid oxide fuel cells, tripling their efficiency. This breakthrough technology is versatile and can be applied to various applications, including solid oxide fuel cells and high-temperature electrolysis.

Researchers have developed a groundbreaking catalyst coating technology for solid oxide fuel cells (SOFCs) that drastically enhances performance within just four minutes. The technology, which employs nanoscale praseodymium oxide catalysts, targets the oxygen reduction reaction at the air electrode, increasing the power output of SOFCs significantly. This new method, which is economical and compatible with existing manufacturing processes, promises broader applications, including high-temperature electrolysis for hydrogen production.

Dr. Yoonseok Choi of the Hydrogen Convergence Materials Laboratory at the Korea Institute of Energy Research (KIER), along with Professor WooChul Jung from the Department of Materials Science and Engineering at KAIST and Professor Beom-Kyung Park from the Department of Materials Science and Engineering at Pusan National University, has successfully developed a catalyst coating technology that dramatically enhances the performance of solid oxide fuel cells (SOFCs) in just 4 minutes.

Fuel cells are gaining attention as highly efficient and clean energy devices driving the hydrogen economy. Among them, solid oxide fuel cells (SOFCs), which have the highest power generation efficiency, can use various fuels such as hydrogen, biogas, and natural gas. They also allow for combined heat and power generation by utilizing the heat generated during the process, making them a subject of active research and development.

Schematic illustrations of the electrochemical coating process on LSM–YSZ electrode of SOFCs. Credit: Korea Institute of Energy Research (KIER)

Challenges in SOFC Performance

The performance of solid oxide fuel cells (SOFCs) is largely determined by the kinetics of oxygen reduction reaction (ORR) occurring at the air electrode (cathode). The reaction rate at the air electrode is slower than that of the fuel electrode (anode), thus limiting the overall reaction rate. To overcome this sluggish kinetics, researchers are developing new air electrode materials with high ORR activity. However, these new materials generally still lack chemical stability, requiring ongoing research.

Photo of the Joint Research Team (Yoon-Seok Choi, Senior Researcher, on the far right). Credit: Korea Institute of Energy Research (KIER)

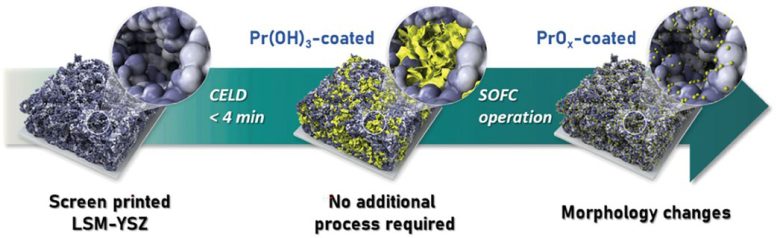

Instead, the research team focused on enhancing the performance of the LSM-YSZ composite electrode, a material widely used in industry due to its excellent stability. As a result, they developed a coating process for applying nanoscale praseodymium oxide (PrOx) catalysts on the surface of the composite electrode, which actively promotes the oxygen reduction reaction. By applying this coating process, they significantly improved the performance of solid oxide fuel cells.

Simplified Electrochemical Deposition Method

The research team introduced an electrochemical deposition method that operates at room temperature and atmospheric pressure, requiring no complex equipment or processes. By immersing the composite electrode in a solution containing praseodymium (Pr) ions and applying an electric current, hydroxide ions (OH-) generated at the electrode surface react with praseodymium ions, forming a precipitate that uniformly coats the electrode. This coating layer undergoes a drying process, transforming into an oxide that remains stable and effectively promotes the oxygen reduction reaction of the electrode in high-temperature environments. The entire coating process takes only 4 minutes.

Additionally, the research team elucidated the mechanism by which the coated nano-catalyst promotes surface oxygen exchange and ionic conduction. They provided fundamental evidence that the catalyst coating method can address the low reaction rate of the composite electrode.

By operating the developed catalyst-coated composite electrode and the conventional composite electrode for over 400 hours, the team observed that the polarization resistance was reduced tenfold. Additionally, the SOFC using this coated electrode exhibited a peak power density three times higher (142 mW/cm² → 418 mW/cm²) than that of the uncoated case, at 650 degrees Celsius. This represents the highest performance reported for SOFCs using LSM-YSZ composite electrodes in literature.

Dr. Yoonseok Choi, co-corresponding author, stated, “The electrochemical deposition technique we developed is a post process that does not significantly impact the existing manufacturing process of SOFCs. This makes it economically viable for introducing oxide nano-catalysts, enhancing its industrial applicability.” He added, “We have secured a core technology that can be applied not only to SOFCs but also to various energy conversion devices, such as high-temperature electrolysis (SOEC) for hydrogen production.”

Reference: “Revitalizing Oxygen Reduction Reactivity of Composite Oxide Electrodes via Electrochemically Deposited PrOx Nanocatalysts” by Seongwoo Nam, Jinwook Kim, Hyunseung Kim, Sejong Ahn, SungHyun Jeon, Yoonseok Choi, Beom-Kyeong Park and WooChul Jung, 22 March 2024, Advanced Materials.

DOI: 10.1002/adma.202307286

The study was conducted with support from the Ministry of Trade, Industry, and Energy’s Core Technology Development Program for New and Renewable Energy and the Ministry of Science and ICT’s Individual Basic Research Program.