How JobPack’s Adaptability Makes Production Scheduling Your Own – Shop Floor Management Software – JobPack

Production scheduling works the way you do with JobPack.

A reliable production schedule that helps you deliver projects on time is a core function for a manufacturing shop. Your company’s reputation, revenue, and growth are built by keeping work organized and meeting customer expectations. And in order to do that, you need the right tools.

Key to production scheduling success is finding a solution that meets your shop’s needs. Many manufacturers still rely on spreadsheets to handle the day-to-day management of their shop floor. But with the increasing complexity of today’s supply chains, old school solutions too often fail to meet modern needs. The built-in scheduling tools offered by an ERP may be a step up from the spreadsheet, but these solutions are often too broad, lacking the robust features necessary to meet the specific needs of your shop floor, or the edge cases that result from your unique client relationships.

JobPack is built to tackle exactly these issues. Lightweight and flexible, JobPack can adapt to virtually any technology ecosystem, integrating with your existing Enterprise Resource Planning (ERP) solution and other shop-floor data streams to start adding value as quickly as possible. Our experts handle the heavy lifting of integration, keeping your IT department free to focus on your day-to-day business needs. The result is a system that fits in smoothly, and provides your team with targeted information in a user-friendly interface.

Here’s how JobPack tailors itself to your requirements for seamless, easy-to-use production scheduling.

JobPack is as ERP-ready as you are.

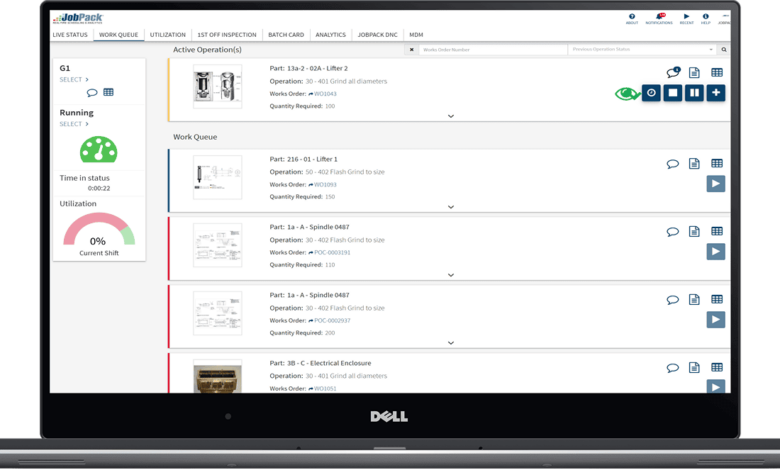

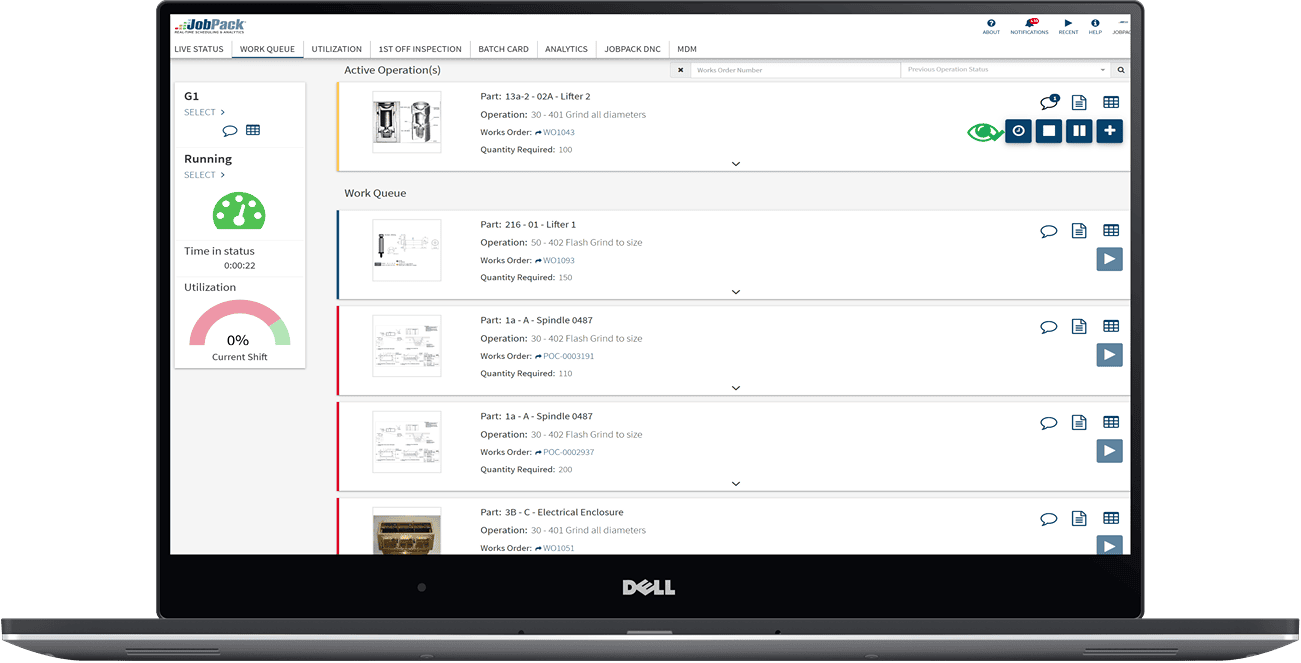

Whether your organization already uses an ERP or you’re looking for your first production planning software, JobPack can help. On its own, JobPack is a powerful production scheduling tool that incorporates Manufacturing Execution System (MES) functionality. It can enhance visibility into your production process, collect machine and workflow data, and help you optimize your shop floor.

JobPack delivers live insight into your shop operations.

In combination with an ERP, JobPack can take advantage of all the data you already collect about your organization to provide even more comprehensive production analysis. Leverage JobPack information alongside ERP data from finance, logistics, HR, and more to develop holistic strategies for improving production.

Automated scheduling leaves room for manual adjustments.

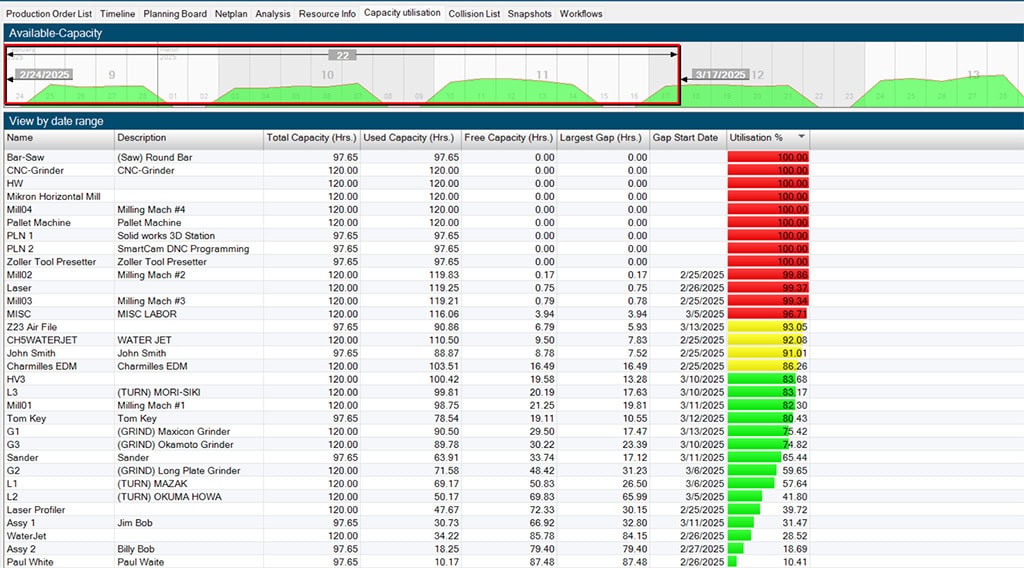

JobPack automatically optimizes your production schedule based on your shop’s working hours, available operators, available machines, and job details—but there’s always room for improvement. Shop circumstances change constantly, and you may be weighing whether to accept a new job or rescheduling shifts to accommodate maintenance. “What-if” scheduling functionality allows you to rearrange your schedule as needed, review the downstream effects, and make your decision without affecting the production environment.

JobPack’s capacity window enables at-a-glance decision making.

More data streams mean more detail.

It’s not just ERPs that JobPack can integrate successfully with. Connect your existing machine monitoring and shop floor data collection systems with JobPack to build a more complete, transparent view into your production floor activity. Or, if your shop isn’t collecting data at this level of detail yet, add the relevant modules to your JobPack implementation to get started.

With these additional data sources, JobPack has more fuel for its analytics. Dive deeper into shop performance and productivity, and investigate the questions you were previously unable to answer. Trace errors back to their root causes with confidence, and uncover marginal efficiency gains that give you an edge over the competition.

Deep dives complement high-level views.

The increased transparency of JobPack has advantages for every level of your organization. A visually intuitive interface lets you glean important information in real time with just a glance—broadcast these views throughout your shop, and operators can benefit as well. At the other end of the spectrum, aggregate data is a useful tool for other parts of the business, like finance, sales, and leadership. Predictive data and productivity over time can support budget estimates, for example, and high-level trends can inform strategy decisions.

The non-production parts of your business aren’t limited to consuming data, either. You can open JobPack to updates from any relevant function in your organization. That way, you’re free to capture any business information that could have an impact on your shop floor.

Call on expert support anytime.

The goal of a JobPack implementation is to make it easier for your staff to do what they do best. Your IT staff have their own day-to-day priorities and strategic goals to meet in order to keep your business running smoothly, and pulling them away from their roles would defeat JobPack’s purpose. Instead, our engineers take point on the work of installing and integrating the software.

And implementation is only the start of a long-term partnership with JobPack. Your organization receives ongoing access to software updates and training materials along with your JobPack installation, and can take advantage of 24-hour support in the event of a problem.

The best production scheduler for your business is the one you’ll actually use.

Even the most cutting-edge scheduling solution on the market needs two things before it can start delivering benefits for your business: first, it needs to be successfully installed; and second, your teams need to be able to use it.

JobPack readily finds its niche in your current tech environment and integrates seamlessly with your existing systems. Its visual interface is intuitive, ensuring your teams will get up to speed quickly, and is structured to provide essential information at a glance. In short, like any top-notch tool, JobPack doesn’t grab attention—it empowers its users to shine.

To see JobPack in action and learn more about what it can do for your shop, contact us today and schedule a free demonstration.

Source link